Article

International Mold Steel adds value by providing solutions to customers

BY LAUREN DUENSING

August 2008

Reprinted with permission from Modern Metals® and Trend Publishing.

PRICE. It’s the main buzzword in the service center industry— at least among companies that sell commodity products.

The employees at Florence, Ky.-based International Mold Steel, however, aren’t concerned about price. They’re concerned about solutions. “Everything we sell is more expensive than the products we compete with,” says Thomas Schade, executive vice president. “We don’t sell generic commodity products like D2 cold work die steel.”

The company’s history goes all the way back to 1975, when Daido Steel Ltd., Nagoya, Japan, introduced NAK55 to the Japanese and southeast Asian plastics mold market. “It quickly became the most popular pre-hardened mold steel in those markets,” says Schade. “NAK was introduced to the North American market by MetalSource [an Alco Standard Co.] in 1982. In 1986, Alco sold MetalSource to U.S. Steel Supply Co.”

In 1991, the company was bankrupt, Schade notes. “At the time of the bankruptcy, I was manager of marketing, specialty steels. Daido asked how to keep the sales of NAK growing, and I sent a business plan for IMS.”

International Mold Steel opened a sales office in Houston in 1991 and moved to a 2,500-square-foot facility in Erlanger, Ky., in 1993 after Okaya USA bought the majority ownership. “We built our current 30,000-square-foot facility and moved in June 1997,” Schade says. “Here we carry all our own inventory and do all our own processing. The original team consisted of four key MetalSource employees: Paul Britton, who currently serves as national sales manager, mold products; Russ Bowen, who spun off to his own business four years ago, Molder’s World, which specializes in one of our technical products; Ernie Beutel, who retired in 2003; and myself.”

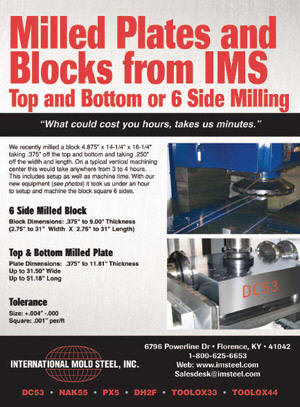

Starting out, International Mold Steel focused its attention on the plastic and rubber mold markets. “We carried only pre-heat treated grades in hardness ranges of HRC 29 to 33 and 38 to 42,” says Schade. “We then approached the cold work die steel market in 2001 with a single grade of steel,DC53, that outperforms most, if not all, the generic grades, such as A2,D2 andM2. This grade has succeeded because it has allowed customers to reduce die fabrication time, extend die life and simplify their lives by only having to buy one grade of steel.” The company is also involved in the aluminum die cast market with Toolox 44 for general applications and “two grades from Daido [DH21 andDH31-EX] that are used in specialized applications requiring exceptional strength to avoid cracking.”

In-house knowledge

As the company grew, it discovered the most important part of selling non-commodity mold and die steel is having the knowledge to back up the product. “We sell on the service side and get involved with the application,” says Britton. “We don’t just take orders and sell steel—we sell mold and die solutions.”

“We’re a relatively small company in personnel so it’s important that each person is technically up to speed,” says Schade. “In the case of Paul, I’ll put him up against almost any rubber mold engineer in the country. Nick Tarkany [national sales manager, die products division] is the chairman of the tool and die division of the Precision Metalforming Association, and, again, when it comes to die design, I’ll put him up against anyone in the country.” Another member of the staff with a similar amount of expertise is Mike Buckley, sales engineer. Schade notes, “He has years of experience designing plastic injection molds, in addition to the hot-runner business.”

The inside sales staff is equally knowledgeable. “Most companies’ philosophy is that inside salespeople wait for the phone to ring and take the order,” Schade says. “Eighty percent of the technical questions that come in never get past Colleen and her inside sales staff. They answer them, and they answer them correctly.”

“We actually get involved with the customer and get to know the customer and the application,” says Colleen Corcoran, inside sales manager. “That helps us to move the process along, but it also helps our outside sales, as well as our managers, to be able to peg that as an important call.”

The staff’s knowledge is so comprehensive that many customers consider the employees to be an extension of their own company. “Paul coined the phrase, ‘We don’t sell steel; we sell mold and die solutions,’” says Schade. “Our sales effort starts with engineers, and one of our first questions is: What are your problems? We then set out to solve those problems. Of course, our goal is to solve the problem with the proper application of one of our steels. But more than once, if there’s another company’s grade that’s more appropriate for a particular situation, we’ll recommend the grade and the source to the customer. In addition to the grade, we also will work on hardness selection, machining and heat treating.”

INTERNATIONAL MOLD STEEL’S INTERNATIONAL REACH MAKES ITS WEB SITE,

www.imsteel.com, an important resource for customers. “We get inquiries from all over on a regular basis,” says Thomas Schade, executive vice president. “A lot of people lean on it as a technical resource.”

The company’s Web site also sells solutions by offering discussion forums and a technical center, which provides answers to commonly asked questions. Paul Britton, national sales manager, mold products division, says the discussion forums “get a lot of hits and are very active. We try to update them on a weekly basis. Most of the questions are answered, and they seem to be well received.

“We don’t sell commodities; we sell solutions,” he notes. “One of our main solution drivers is the quality of our steel. We try to teach people more about our steel. It’s a learning experience for both our customers and us, and that’s why we use the discussion forums that way.”

Since their inception, the forums have been an informal place for customers to learn more about International Mold Steel’s products. That’s still the case, but recently the forums have received an upgrade, in addition to better security. “These forums are relatively new,” says Nick Tarkany, national sales manager, die products division. “We’ve been using them off and on, but we haven’t gone out full-fledged to advertise them. We’re at the point now where we’re ready to do that. Your questions are welcome, the security is great and we’re moving forward.”

“When a customer feels that you’re an extension of their engineering staff, that’s high praise,” says Britton. “There are times when a customer will call us looking for a certain grade of steel, and we’ll send them in a whole different direction.”

Britton says even if International Mold Steel recommends a grade it doesn’t sell, the customer “gets the information from us, they view us as the resource and nine times out of 10, we’re the first phone call.”

Corcoran says the company also receives “quite a few leads from Europe and India. We either tackle that ourselves and ship from this location or we have a European distributor that we work closely with. Between those two, we’re extending ourselves in every direction.”

Another aspect of the company’s international network comes through its partnerships. “Daido is an equity partner in the company,” says Schade. “Our relationship with SSAB [Oxelosund, Sweden] is rapidly becoming closer than vendor-customer.” In addition, he says International Mold Steel considers HE&M Saw a partner, as the company exclusively uses its saws.

“As the volume forDC53 grew out of our capacity, we partnered with Alro Steel [Jackson, Mich.] as our first, and largest, distributor,” he says. “The customers in the territories they serve benefit from their excellent service. We supply Alro with technical support. We’ve entered into similar relationships with Lindquist Steels in New England, Southern Tool Steel in the South, Hudson Metals in the West and Titus Steel in Canada.”

Cost savings

International Mold Steel is always looking for the next solution, whether through an engineering discovery or a new grade. “We select grades that Daido produces that become popular in the Japanese market because they dramatically outperform the generic grades,” says Schade. “We test the machining, grinding and polishing extensively, both in-house and with selected customers. When we’re comfortable that the new grade, even though the initial acquisition cost of the metal is somewhat higher than the grades we compete with, will, through reduced machining and grinding time and extended tool life, reduce our customers’ tooling cost per part, we introduce the grade. The testing also allows us to be technically proficient and fully capable of showing our customers how to benefit from the unique features of the steel.”

Customers benefit from a one-source supplier. “Our customers don’t have to worry about inconsistent quality from multiple supplying mills,” Schade notes. “We recently added our first two grades not produced by Daido. They are Toolox 33 and Toolox 44, produced by SSAB. We put these grades through the same extensive testing. When they surpassed our expectations, we decided to carry them. Due to the unique manner these steels are manufactured, only SSAB can make them. Again, we have the advantage of single source reliability and quality.”

The quality of International Mold Steel’s products can result in enormous cost savings for customers. “We had a rubber mold customer that was using a grade of stainless for his mold cavity plates,” says Britton. “They were cracking and breaking just about every week, and they were costing him about $3,000 per week to replace. We switched him to a DC53, and he actually paid 10 percent more than the 440 stainless.” Britton says that because the cavities stopped breaking, the customer was able to use less rubber and hold tighter tolerances, and his scrap went down. “Spending 10 percent more on steel for that one part saved him $1.2 million in a year in tooling and scrapped parts.”

That’s not the only customer who’s saved a bundle. Another replaced a blade that was being imported from China with a DC53 blade with a coating on it. “They were paying $186 for this blade, and we charged them$415,” Britton notes. “They said, ‘Accounting is never going to go for this.’ Their production cycle on the Chinese blade was lasting two hours, and then the blade would be dull. Our blade lasted six days. It ended up saving them about $53,000 per year in blades.”

What customers learn from working with International Mold Steel is that the up-front cost of material doesn’t need to be the deciding factor. “The key is teaching customers not just to look at variables A, B and C but to look at A through Z,” says Tarkany. “Look at the starting cost and the bottom line. Our steel will save money on the bottom line.”

And that bottom line is what matters to customers. “I had a customer tell me yesterday, ‘That’s the way we’ve done it for 80 years, and we need to change,’” says Tarkany. And that customer has come to the right place looking for a solution.

“We’ve found the people that we end up doing the most business with are the forward- thinking people, who are always looking for new and better ways to do things,” says Schade. He notes that even in this tough economy, “they’re all busy. The people who are beating their heads against the wall saying, ‘We do it this way, we’ve always done it this way, and we’re not about to change because we’re comfortable’ are the people that are struggling.”

International Mold Steel Inc., Florence, Ky.,

Tel: 859.342.6000,

Fax: 859.342.6006,

Eeb: www.imsteel.com

E-mail: [email protected]