DCMX

DCMX is a matrix-type cold work tool steel

DCMX is a matrix-type cold work tool steel: only fine carbides are distributed in matrix due to optimum alloy design and production process.

DCMX shows high performance in service and ease in mold making as well.

Applications include:

Punches

Dies

Working Tools for Cold Pressing and Cold Forging

Cold Stamping Dies for High Strength Steels

Insert Blocks for Composite Stamping Dies

Blanking Punches and Trimming Edges

- High hardness such as 62 HRC is available by high temperature tempering with good dimensional stability, resulting in high wear resistance

- High toughness helps to prevent cracking and chipping.

- Isotropic dimensional change works easy geometry control in heat treating.

- Machinability is improved by free machining additives and finely dispersed carbides.

Product Brochure

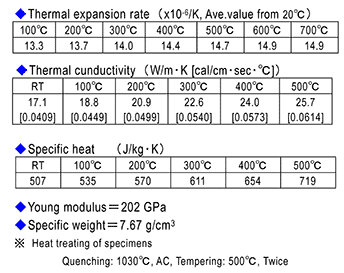

Physical Properties

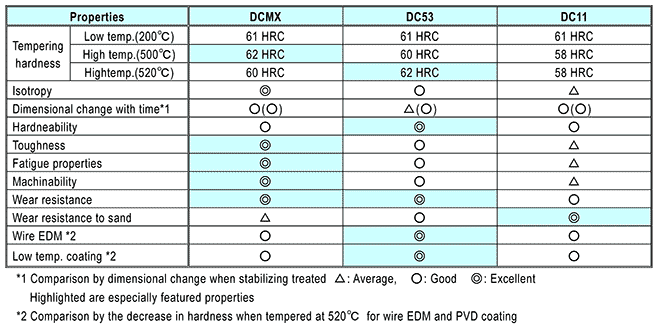

Die Performance  Comparison of properties among Daido cold work die steels:

Comparison of properties among Daido cold work die steels:

- High hardness such as 62 HRC is available by high temperature tempering with good dimensional stability, resulting in high wear resistance.

- High toughness helps to prevent cracking and chipping.

- Isotropic dimensional change works easy geometry control in heat treating.

- Machinability is improved by free machining additives and finely dispersed carbides.

Comparison of properties among Daido cold work die steels:

Comparison of properties among Daido cold work die steels:

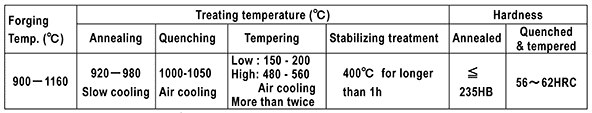

Heat Treatment

Heat Treatment

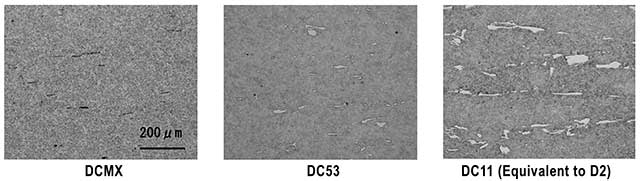

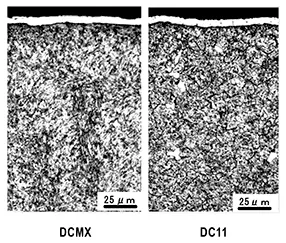

Optical Micrographs (Annealed)

DCMX shows fine microstructure almost free from coarse carbides

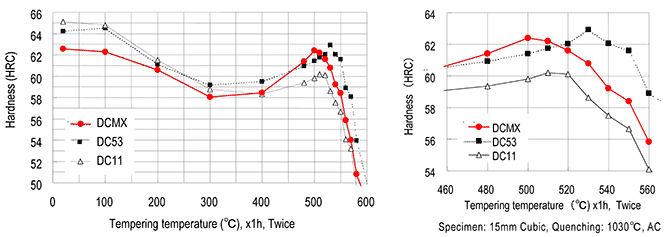

Tempering Hardness

Dimensional Stability

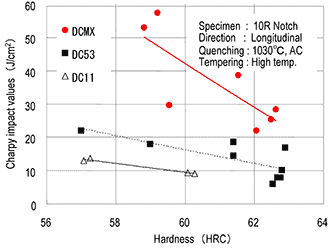

Toughness

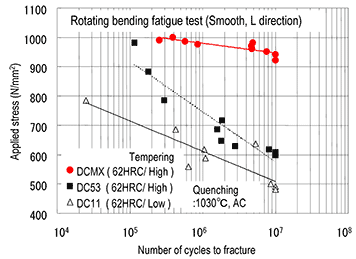

Fatigue Properties

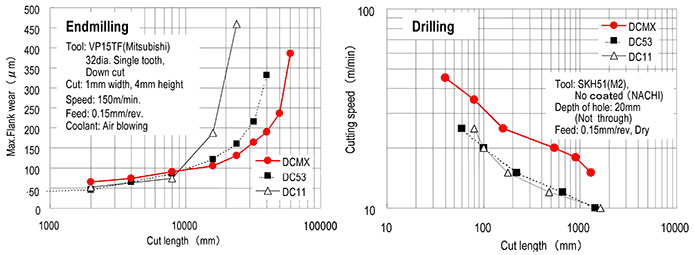

Machinability (Annealed)

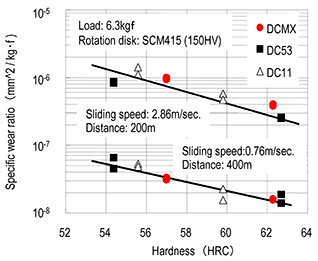

Wear Resistance (Ohkoshi-test)

TD Coating

TD coating: By courtesy of DOWA Thermo Engineering.

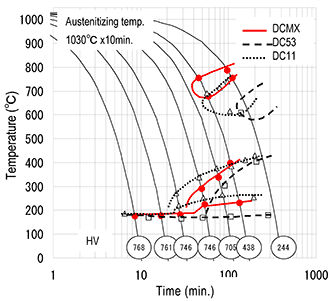

CCT Diagrams

Optical Micrographs (Annealed)

DCMX shows fine microstructure almost free from coarse carbides

Tempering Hardness

Dimensional Stability

Toughness

Fatigue Properties

Machinability (Annealed)

Wear Resistance (Ohkoshi-test)

TD Coating

TD coating: By courtesy of DOWA Thermo Engineering.

CCT Diagrams

BENEFITS

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

MECHANICAL PROPERTIES

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

PHYSICAL PROPERTIES

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

CHEMICAL COMPOSITION

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.