DH31-EX

High strength, tough and high heat check resistance hot work die steel.

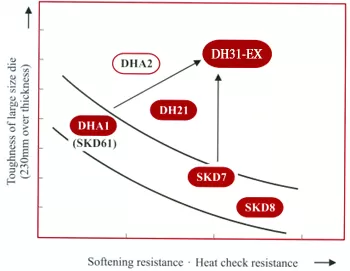

DH31-EX is a hot working die steel with the best balance of strength and toughness showing the comparable softening resistance to SKD7 and twice hardenability as that of SKD61.

Applications include:

Aluminum Die Cast Dies

Aluminum Die Cast Parts

Hot Forging Dies

Hot Pressing Dies

Aluminum Extrusion Dies

- High hardenability

High toughness is obtained even in large size die. - High strength

High softening resistance at elevated temperature contributes to high wear resistance. - High toughness

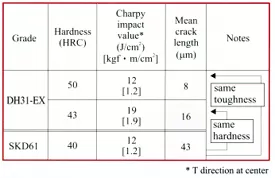

DH31-EX has higher toughness than that of SKD61. - High heat check resistance

Excellent heat check resistance leads to longer life.

Product Brochure

PHYSICAL PROPERTIES

Coefficient of thermal expansion

Specific heat

Thermal conductivity

Density

Characteristics

Tempering hardness

- Quenching temp: 1030°C

- T.P. size: 10H x 10W x 15L

Softening resistance

- Holding temp.: 600°C

- Quenching temp: 1030°C x 30min. –> 150 Dia. Bar, AC

- T.P. size: 10H x 10W x 15L

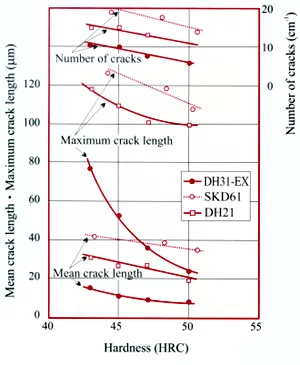

Heat check resistance

An example to improve heat check resistance (200mmm thickness air cool quenched die)

<Test procedures>

- Specimen: 15mm

- I/Heating: 20<-> 700C

- Number of cycles: 1000 times

Toughness

- Quenching temp: 1030°C x 30min. –> 150 Dia. Bar, AC

- T.P. size: L

Elevated temperature tensile properties

- T.P. size: Ø 8 x 40L

Erosion resistance

Creep properties

Hardenability

Continuous cooling transformation curve

Bainite hardenability

Quenching cooling time vs. toughness

Cooling time of mid portion from 1030°C to 300°C (min)

TP size: Ø440

Quenching temp: 1030°C

Surface Hardening Properties

PS, PW process

- Daido Amistar’s originally developed process.

- PW process improves wear, fatigue and corrosion resistance.

- PS process improves scuffing and erosion resistance.

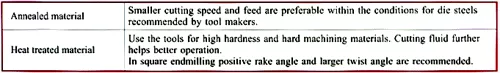

Machinability

- DH31-EX shows good machinability as high strength-high tough grades.

- Recommended machining conditions

Repair Welding Conditions

- TIG manual welding condition

BENEFITS

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.