Cold Work Steels

Recommended Reading

High-performance Coating Helps Stamper Fight Downtime

Reprinted with permission from

The Croydon Group, Ltd.

Dies last longer, need no regrinding.

New CrN Tool Coatings Keep Going and Going and Going…

Metal Forming Magazine

Phygen PVD-applied chromium-nitride coatings on deep-draw tools, form tools and cutting-tool edges last longer than other coatingsIs It Tough Enough for You?

Can a new tool steel that machines like butter really be tough enough to withstand the pounding that a Tier One automotive stamping plant will put it through? We ask an “old D-2 boy” what he thinks.

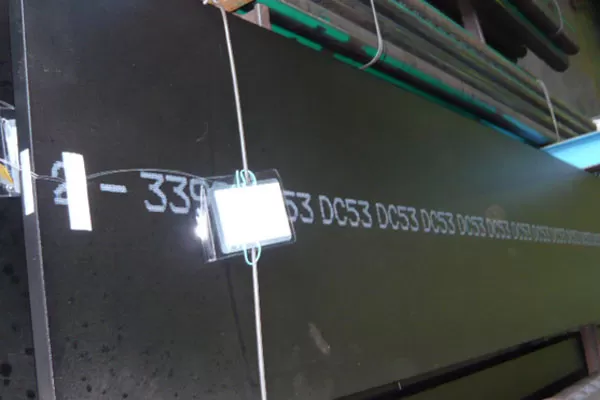

DC53

DC53 is a general purpose cold work tool steel with exceptional Toughness, Wear Resistance, Compressive Strength and Temper Resistance.

Unique Characteristics:

- Uniform distribution of fine carbides

- Excellent galling & wear resistance

- Exceptional toughness & fatigue resistance

DC53 Punch Stock

DC53 is a general purpose cold work tool steel with exceptional Toughness, Wear Resistance, Compressive Strength and Temper Resistance.

- Uniform distribution of fine carbides

- Excellent galling & wear resistance

- Exceptional toughness & fatigue resistance

DCMX

DCMX is a matrix-type cold work tool steel: only fine carbides are distributed in matrix due to optimum alloy design and production process.

Unique Characteristics:

- High hardness such as 62 HRC is available by high temperature tempering with good dimensional stability, resulting in high wear resistance

- High toughness helps to prevent cracking and chipping.

- Isotropic dimensional change works easy geometry control in heat treating.

TOOLOX 44

TOOLOX 44 is a new quenched and tempered tool steel designed to have high impact and low residual stresses and therefore good dimensional stability.

Unique Characteristics:

- Despite hardness of nominal 45 HRC, this new steel is easy to machine.

- Great for guide rails, bending tools, etc. when high stability materials are required.

TOOLOX 33

TOOLOX 33 is a quenched and tempered tool steel designed to have low residual stresses and extremely good machinability.

Unique Characteristics:

- Especially suited for plastic molds and rubber molds, having excellent polishing and photoetching ability.

- Supplied in plate thickness 3/4” – 5 1/8”.

- Hardness 30-35 HRC.